Roll Fed Square Bottom Paper Bag Making Machine

Features:

| Cutting Length | 270-530mm |

| Cutting Length(handle) | 270-430mm |

| Paper bag grams(handle) | 80-150g/㎡ |

| Inner diameter of paper core | 76mm |

| Paper rope diameter by hand | 3-5mm |

Features:

| Cutting Length | 270-530mm |

| Cutting Length(handle) | 270-430mm |

| Paper bag grams(handle) | 80-150g/㎡ |

| Inner diameter of paper core | 76mm |

| Paper rope diameter by hand | 3-5mm |

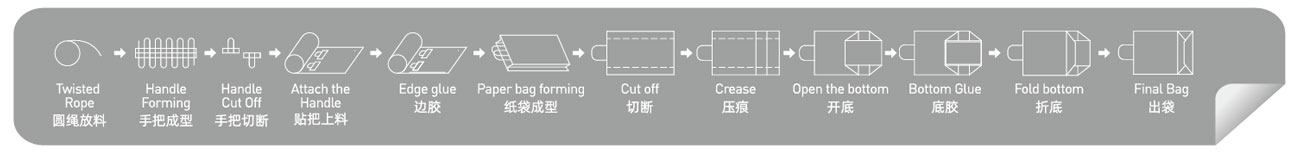

Roll Fed Square Bottom Paper Bag Making Machine is used to complete the square bottom paper bag withhandle in one time using web paper and paper rope as raw materials. lt is the ideal equipment for therapid production of hand carry handbags. This Square Bottom Paper Bag Making Machine is especially suitable for the production of foodbags, portable shopping bags and other environmental protection packaging paper bags. This machine completes the steps of handlebar making, handlebar pasting, paper tube forming, paper tube cuttingand bag bottom forming at one time. This machine adopts Japan mitsubishi high speed motioncontroller (CPU), through the high speed bus control servo operation, to ensure the stability of motionsmooth motion curve, intelligent interface operation, truly realize the full automation production, caneffectively save labor costs. lt is the first choice for the production of food and clothing bags and otherportable paper bag equipment.

1. Using Willon touch screen man-machine interface, the operation function is clear at a glance. easy to control

2. Adopting Japan original Mitsubishi motion controller, through the integration with the opticalfiber, operation stability

3. Adopting Japan Mitsubishi servo motor with German Schick color standard eye correction.accurate tracking printing bag size

4. Hydr aulic lifting structure is used for raw material loading and unloading and automatic constant tension control

5. Brush less servo motor is used for raw material correction to reduce the alignmentadjustment time of paper roll

| Model | XL-FD350Y | XL-FD450Y |

| Cutting Length | 270-530mm | 270-530mm |

| Cutting Length(handle) | 270-430mm | 270-430mm |

| Paper Bag Width | 120-330mm | 220-450mm |

| Paper Bag Width(handle) | 200-330mm | 240-450mm |

| Bottom width | 60-160mm | 90-160mm |

| Paper bag grams | 60-150g/㎡ | 80-150g/㎡ |

| Paper bag grams(handle) | 80-150g/㎡ | 80-150g/㎡ |

| Wrap width | 380-1050mm | 650-1290mm |

| Wrap width(handle) | 570-1050mm | 690-1290mm |

| Diameter of paper | 1300mm | 1200mm |

| Inner diameter of paper core | 76mm | 76mm |

| Hand patch width | 152mm | 190mm |

| Hand patch width | 40mm | 50mm |

| Paper rope spacing | 75mm | 95mm |

| Paper rope diameter by hand | 3-5mm | 3-5mm |

| Width of patch paper roll by hand | 100mm | 100mm |

| Paper roll diameter by hand | 1200mm | 1200mm |

| Hand patch paper weight | 100-135g/㎡ | 100-135g/㎡ |

| Mechanical speed | 30-200bags/min | 30-180bags/min |

| Paper bag speed | 30-180bags/min | 30-150bags/min |

| Handheld speed | 30-150bags/min | 30-130bags/min |

| Cutting Tool Mode | Serrated cutting | Serrated cutting |

| Switchboard power | 380V/ 3phase 4line 41.5kw | 380V/ 3phase 4line 41.5kw |

| Total weight | 15000kg | 15500kg |

| Machine size | 14000*6000*2400mm | 14000*6000*2400mm |

GET A QUOTE