HighSpeed V Bottom Paper Bag Machine

Features:

| Paper width | 160-780mm |

| Maximum diameter of paper material | 1000mm |

| Inner diameter of paper | 76mm |

| Paper thickness | 35-80g/㎡ |

| Power | 380v 3phase 4line 24kw |

Features:

| Paper width | 160-780mm |

| Maximum diameter of paper material | 1000mm |

| Inner diameter of paper | 76mm |

| Paper thickness | 35-80g/㎡ |

| Power | 380v 3phase 4line 24kw |

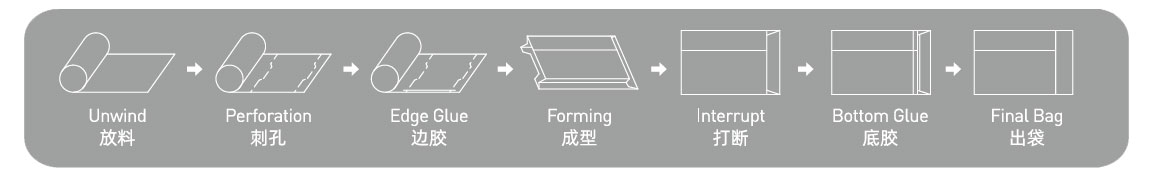

HighSpeed V Bottom Paper Bag Machine use primary color rolling paper or printed rolling paper such as kraft paper, striped brown paper, slick paper, food coated paper, medico paper and SO on, bag making process consist of puncture, side gluing, sidefolding, bag forming, cut off, bottom folding, bottom gluing, finish product delivered in onetime. Our machine have advantage of easy operation, high effeciency, more steady, it is an idealmachine for make differnt kind of paper bag, snack food paper bag, bread paper bag, dry fruitpaper bag and environment friendly paper bag.

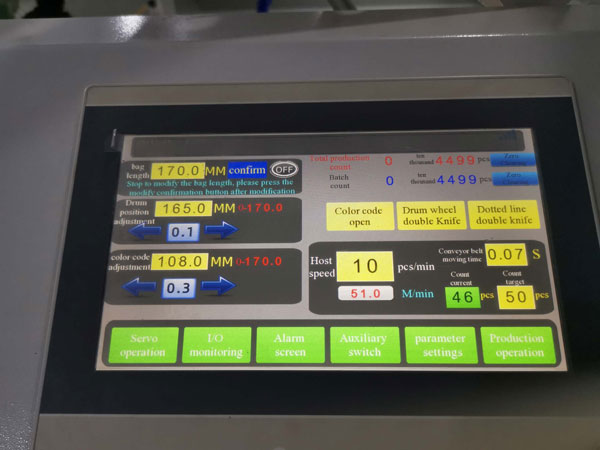

1. The man-machine interface of willon touch screen is adopted, the operation function is clear at a glance, easy to control

2. Adopting Japan original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

3. Adopting Japan Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4. The loading and unloading of raw material adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control

5. Brushless servo motor is used to correct the deviation of raw material and reduce the adjustment time of paper roll alignment

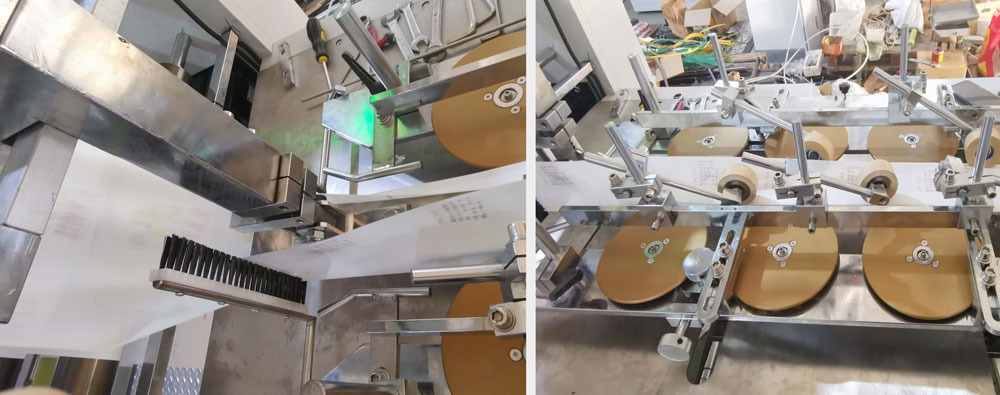

The machine has the function of opening Windows

Adopt touch screen and PLC programming control system, the work condition can be shown real time. Cooperate with the ultra precise double servo motor, the stability can guaranteed,remote control helps you solve the problem.

Adopt Janpan mitsubishi servo motor control system to realize high speed and precise operation control

Precise color mark tracing system can make sure precision of bag printing pattern cutting position. The color mark tracing function can avoid the readjustment after paper reel changing, paper web breaking, or power outage. The machine can stop auto when the color mark is erro. It will save time and reduce the waster rate.

The integral tube forming adjustment structure can be adjusted at the same time on one side or both sides to improve work efficiency, reduce the scrap rate generated by the adjustment process and save adjustment time and stability of adjustment.

Peneumatic paper reel lifting device make paper reel changing easy. Press one switch and the paper reel will be lifted auto. Avoid the person injury. The pneumatic lifting system can make sure the stability of paper web feeding and avoid moving feeding stand.

The high speed servo puncturing system pre-cut the material by the tooth knife. It make the bags more pricision, evenly and beautiful. It could be used for more materials.

| Model | XL-JD260 | XL-JD350 |

| Cutting Length | 120-400mm | 320-650mm |

| Bag length (L) | 100-385mm | 300-640mm |

| Bag width (W) | 80-260mm | 70-350mm |

| Insert size (G) | 20-80mm | 20-120mm |

| Ladder height | 15/20mm | 15/20mm |

| Paper bag speed | 100-600 pcs/min | 100-400 pcs/min |

| Paper width | 160-780mm | 160-780mm |

| Maximum diameter of paper material | 1000mm | 1000mm |

| Inner diameter of paper | 76mm | 76mm |

| Paper thickness | 35-80g/㎡ | 35-80g/m² |

| Working gas | ≧0.12m³/min,0.5-0.8mpa | ≥0.12m/min,0.5-0.8mpa |

| Power | 380v 3phase 4line 24kw | 380v 3phase 4line 24kw |

| Total weight | 3500kg | 3500kg |

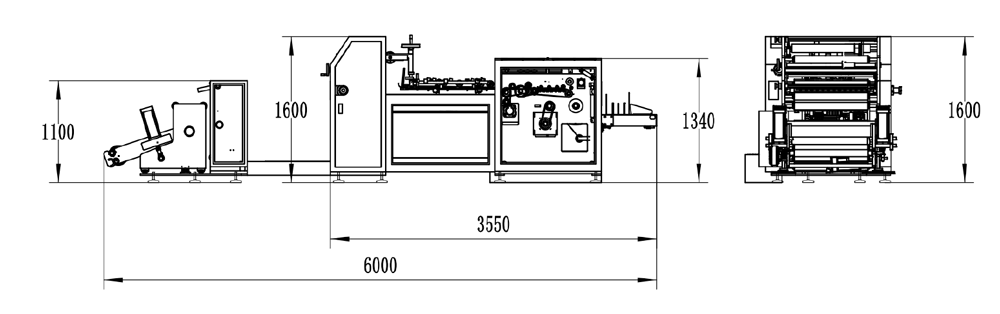

| Dimension | 6000*1600*1700mm | 9100*1900*1950mm |

GET A QUOTE